Podcast: Play in new window | Download | Embed

Subscribe: Apple Podcasts | RSS

OK, so OSHA has sent out an update for communication tower workers, https://www.osha.gov/doc/topics/communicationtower/index.html for the OSHA site. So what changed? Here is the PDF for the information, https://www.osha.gov/OshDoc/Directive_pdf/CPL_02-01-056.pdf but let me tell you how I read it. First off, let me tell you that I am happy that OSHA is addressing this and I am happy that NATE and OSHA are working together to make the climbers life safer and easier. I appreciate the attention to the industry.

Apologies for the long post but I just couldn’t stop writing! It’s mostly my interpretation of the release, so make sure that you read it yourself, don’t take my word for it! Read it!

Subscribe to the podcast! Write a review! Show me you listen!

From the bulletin DIRECTIVE NUMBER: CPL 02-01-056. It covers work using a hoist to lift personnel, (that would be you the climber), from their workstations, (assuming that would be from the ground to somewhere on the tower). The preferred way to access workstations on the tower is to climb a fixed ladder with attached climbing devices, (most tower have something today, but not all). So here is the news, if the climber will be working at one area and making multiple trips, then materials and the worker shall be hoisted to the work level. I am going to give my view here but I highly recommend that you read it, the link is above.

Listen, here is the reality I worked in, when I got on the tower I only got down for 2 reasons, 1) when the job was finished for the day or 2) if it was time to eat and we didn’t bring anything to the site to eat. I often spent 10 hours or more on the tower. There were days where I could spend 2 hours on a tower just to go to the next tower to do maintenance or repair. Time is money. Now, if I was on the tower for that long we would hoist up large items but smaller items we would often pull up by hand. This could address that particular part of the job. That does cause fatigue so why not have the winch do it. I am all for that.

If you are going to hoist employees, better know what winch to use and you had better know what you’re doing. Let’s review the definitions section. 1) Anti-Two block device, read this because this is a safety feature. 2) Maximum load, better know your limits! 3) Competent person on site, do we really have to stress this every time? YES! Because apparently this is still missing from many work sites! 4) Qualified person, again Mr. Obvious, YES! 5) Gin Pole, different rules apply to the Gin Pole and this should be a competent crew and something that is covered separately, 6) Engineered hoist systems, covers the complete hoisting system end to end, do you know and understand this system? Are you competent on the entire end to end system? Are you? Seriously, are you?

Hoisting personnel and training: there is that part again, training, have you been trained properly? No joke, have you been trained properly and do you feel confident using the hoist. I am not asking if you know all hoists or winches, just the one you are working on, that particular hoist. If you are making jokes right now, then maybe you should be looking for a new line of work.

I am not going to cover the equipment in-depth here, that’s your job! This section is very important and you should read it. First off make sure that a professional engineer approved your hoist system by stamping off on it. Check lines and slings. Load capacity should be at least twice what the load will be. Use a guide line to keep employees and loads off the tower. This is something that should not be taken lightly; tagging is critical and is something that a competent person should do if the load is a human. Use a foot block for people, obvious to me. Gin pole is on there, but if you are using a gin pole then your crew should be competent on a gin pole. Post the load capacity near the winch, this is something that is a great idea to keep everyone on the same page.

Trial lift and proof testing, this is something that should be part of the training and testing when you get the equipment. This should apply to more than your hoist or winch, this should apply to most of your equipment and safety gear. This section gives you a good outline of what you should be doing. It would be a good place to start for your testing.

Pre-Lift meeting: this is a great idea that you could add to your daily meetings and on every work site prior to doing the work.

I am not going to go over documentation, this should be obvious.

Hoisting employees to and from the workstation – this section you should read! I am not going to cover it because I feel this should be read direct and you should understand it. I don’t want you thinking that I can cover this at a high level and then you understand the requirements!

Communications between the operator and the hoisted employees. If you work together I would like to think you already have a system. I think it would be better if you had radios to communicate but if you rely on visual, make sure you worked it out ahead of time. I added a crane signals section in my Field Workers Aid book but I highly recommend that you all get on the same page in the Pre-Lift Meeting prior to any work. Also, don’t let the blind guy work the lift. I would also ask that if you have someone who is easily distracted, then maybe they shouldn’t be running the lift either.

OK, you should read the rest, this is long enough and I am sorry I droned on. I will have more in the podcast if you really want to hear more.

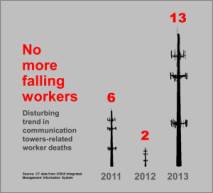

Remember this letter in February? https://www.osha.gov/doc/topics/communicationtower/Letter_CT_Employers.html that OSHA sent out to companies. Apparently most companies didn’t listen. I guess not everyone follows NATE and OSHA like they should. I will tell you this, most of the climbers I talk to and I communicate with not only follow NATE and OSHA but they respect what they are trying to do. I am not saying they agree with everything, but they understand that this is a process and that we all want the same thing, 0 fatalities if at all possible. Especially 0 fatalities that involve stupidity or lack of experience. We need to educate each other with real world experience to make sure that this becomes reality. Even though we all compete for work we all need to work together and share experience to make sure we make this industry the safest it can be. In the USA we have so many rules and safety processes in place and yet this industry is so dangerous. I know I give the carriers a hard time but I guarantee you that all of the people there want the same thing we do, 0 accidents if at all possible, they have the same goal. We all have the same goal, so let’s start working at it. The best place to start is training and education. That means we have to start with all of the companies and make sure that they care about their employees as a human, a living person, someone with a family. Then we can start to make progress towards a safer industry. It takes responsibility, not just the company but for each of you to look out for your work mate. It seems most people who read this feel that way and yet you read about workers who can’t help each other or companies that send workers out by themselves. It is time for OSHA to seriously look at all of these accidents. Let’s take this discussion away from Facebook and start by talking to each other at the tower sites, face to face. Let’s talk to each other in the field, in a friendly way, to make the newer climbers understand that inexperience and carelessness kills in this business, literally. And with that said, if there is a loss, let us respect the families since we seem to never know what happened until months later.

NATE memo;

Articles;

http://ehstoday.com/safety/osha-directive-outlines-proper-use-hoists-tower-workers

http://thehill.com/regulation/213241-new-osha-rules-would-protect-tower-workers-from-falling

Jon L. Gelman wrote about it here, http://workers-compensation.blogspot.com/2014/07/osha-issues-new-directive-to-keep.html?utm_source=twitterfeed&utm_medium=twitter if you want an overview.

Whistle blower information;

http://www.mondaq.com/article.asp?articleid=330216

http://www.regulations.gov/#!documentDetail;D=OSHA-2011-0540-0001

Other information!

Don’t forget to take the poll for jobs!

Remember that the Hubble Foundation needs your support. Show you care for the families of the fallen and the fellow climbers in need. They still have tickets to the car giveaway! Support Hubble, honor the fallen, and maybe win a Mustang!

I am working on 2 new projects, a new book that outlines my different jobs in the industry and a library of reference material that you can access quickly to take to the site. I want to see you make the site safer with quick reference material. If you have any idea of what you need out there let me know. Show me you care, Facebook, wade4wireless@gmail.com or leave a comment or leave a message at 510-516-4283