Podcast: Play in new window | Download | Embed

Subscribe: Apple Podcasts | RSS

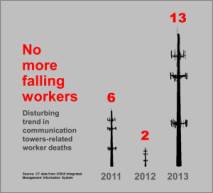

First off I would like to pay my respects to the 49-year-old fallen tower painter that passed on 7/10/2014. Rest in Peace Thomas Lucas, you will be missed, gratitude and love out to your family. This is the ninth fatality in 2014, and let us all pray that this is the last! I put some tower painting videos in here to honor him. For more information go here.

Thank you for the feedback on the near miss stories. I got several responses immediately. I am doing this so people can learn from the mistakes that others made. These are lessons learned. For those of you that don’t understand this, let me clarify. When you’re at a site telling someone what you plan to do, do they just say OK and walk away? Or, do they say “this is what I would do” and “this is what I tried in the past” and “here’s why it didn’t work”. I would always offer my ideas and opinions at the site, it is up to the current crew as to whether they want to use it or not.So let’s learn from these!

As soon as you can please subscribe and write a review on iTunes or Stitcher today!

Search in iTunes Wade4Wireless Blogcast. Thank you!

Each story is told by the person who sent it in. I took out any names, company names, or customer names.

Story 1: We used a hemp rope they tried to drop a 10′ dish and the mount, this was about 10 years ago when nylon ropes were new. Well, because we didn’t tag the dish, we tried to drop it straight down a self supporter. (For those that don’t know self supporters get wider at the bottom!) Well it was fine until if got snagged on the tower, so then we tried to pull the dish back up. Guess what, the rope could not pull it back up so the dish dropped, hard, and flattened one site. However it didn’t just fall straight down, it hit the tower and bounced inside the tower! Flattened on side of the dish and looked really bad. Luckily, they (customer) didn’t plan to reuse it and sent it in for scrap. No injuries, no one was hurt, and an important lesson was learned that we need tag lines and patience. Lesson learned!

Story 2: Just this past Friday I was working on a raw land site where the tower had been stacked the previous day. Myself and one other man( a rookie to my company) were shaking down the tower. I had gone up and done a tape drop and came down tightening one legs gussets and center stitch. The man with me had helped stack the previous day. He did great! 100% tied off, climbed well, didn’t drop any tools, kept his hands out of pinch zones and listened to direction from crew chief very well. The stack went awesome. He went up to tighten down another leg and center stitch. He got down to the forty-foot mark and at this time I was going thru hardware to see what was left and organize for the next crew coming in to fly waveguide and build a carrier’s site. There was some hardware on the pier at base of tower and without hesitation I went to gather it. At that moment he slipped while standing on the two downward diagonals and the spud socket wrench he was using came free. It hit me, bent over, in the back just below my shoulder-blade from forty feet. It landed socket end first and the alignment pin slapped down after. I WAS LUCKY!! I’m bruised but not broken.

Story 3: We loosened the mount with a 2 man crew, thinking that the mount and the antenna would not be too heavy. It took a long time for me, on the tower, to break all the clamps. The hardware was tight and it took a long time to take off. Well as soon as I took the last mount off the load was so heavy that the guy on the ground got pulled into the block on the ground. He couldn’t hold it so we both tried to slow it down but it would not stop! We had to let it fall. Busted the antenna but didn’t hit anything on the ground! We got lucky, just a couple of bloody hands bit no real injuries. A bad day we walked away from.

That’s it for this week. Keep the stories coming.Email me at wade4wireless@gmail.com or message me on Facebook or leave the information below. Or call and leave a message at my Google voice mail at 510-516-4283. Remember it here.

In honor of the fallen climber, here are some painting videos:

FYI: PEAK Career Services, a division of Pinnacle Career Institute is working with an International Engineering Firm to hire and train a significant number of entry-level Tower Technicians in order to meet rising demand in the Telecommunications Industry. Candidates chosen for this opportunity will participate in an intensive 1-week training program at no cost to them. There are several locations throughout the United States. Visit www.peakpci.com for more information or email contact@peakpci.com. To apply go to www.peakpci.com/apply-now

You could always subscribe!

[emailpickup api_name=”INinbox”]

We need the Hubble Foundation now more than ever, and they need your support. Will you give today?

My Books on Kindle:

My PDF books on Sellfy, Pay with PayPal:

My PDF books on GumRoad, Pay with Credit Card:

Whistle blower information;

http://www.mondaq.com/article.asp?articleid=330216

http://www.regulations.gov/#!documentDetail;D=OSHA-2011-0540-0001

By the way, I am planning to put out some more books, this time on scopes of work, Bill of materials, and other useful information for the workers. Let me know what you think. I am working on 2 new projects, a new book that outlines my different jobs in the industry and a library of reference material that you can access quickly to take to the site. I want to see you make the site safer with quick reference material. If you have any idea of what you need out there let me know. Is this going to help you? Let me know on Facebook, wade4wireless@gmail.com or leave a comment or leave a message at 510-516-4283

Next post will be about fines.